Esontweni elandulela leli, sethule inqubo yokuvala ama-filimi capacitor, futhi kuleli sonto ngithanda ukukhuluma ngobuchwepheshe obubalulekile bama-capacitor amafilimu.

1. Ubuchwepheshe bokulawula ukushuba njalo

Ngenxa yesidingo sokusebenza ngempumelelo, ukujikajika kuvame ukuba phezulu kakhulu kuma-microns ambalwa.Futhi indlela yokuqinisekisa ukungezwani okuqhubekayo kwezinto zefilimu enqubweni yokuvuthwa kwesivinini esiphezulu kubaluleke kakhulu.Enkambweni yokuklama akufanele nje sicabangele ukunemba kwesakhiwo semishini, kodwa futhi sibe nohlelo oluphelele lokulawula ukungezwani.

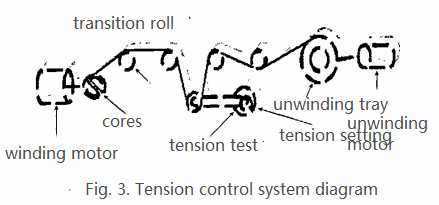

Uhlelo lokulawula ngokuvamile luqukethe izingxenye ezimbalwa: indlela yokulungisa ukushuba, inzwa yokubona ukushuba, injini elungisa ukushuba, indlela yokuguquka, njll. Umdwebo wohlelo lwesistimu yokulawula ukushuba uboniswa kuFig. 3.

Ama-filimi capacitor adinga izinga elithile lokuqina ngemva kokusonteka, futhi indlela yokuqala yokujika iwukusebenzisa intwasahlobo njengokumanzisa ukulawula ukushuba kwesimo esongwayo.Le ndlela izodala ukungezwani okungalingani lapho i-motor ejikelezayo isheshisa, incipha futhi ima ngesikhathi senqubo yokujika, okuzokwenza ukuthi i-capacitor iphazamiseke kalula noma ikhubazeke, futhi ukulahlekelwa kwe-capacitor nakho kukhulu.Enqubweni yokusonta, ukungezwani okuthile kufanele kugcinwe, futhi ifomula imi kanje.

F=K×B×H

Kule fomula:F-Ukungezwani

K-I-tesion coefficient

B- Ububanzi befilimu (mm)

H-Ukujiya kwefilimu(μm)

Isibonelo, ukushuba kobubanzi befilimu=9 mm nogqinsi lwefilimu=4.8μm.Ukushuba kwayo ngu-:1.2×9×4.8=0.5(N)

Kusukela ku-equation(1), ububanzi bokungezwani bungase buthathwe.I-eddy spring enomugqa omuhle ikhethwa njengesilungiselelo se-tension, kuyilapho i-potentiometer yokungeniswa kazibuthe engathinteki isetshenziswa njengokutholwa kwempendulo ye-tension ukulawula i-torque ephumayo kanye nokuqondiswa kwe-DC servo motor engavuliyo ngesikhathi senjini ejikajikayo, ukuze ukushuba ihlala njalo kuyo yonke inqubo yokugoqa.

2. Ubuchwepheshe bokulawula amawindi

Amandla we-capacitor cores ahlobene eduze nenani lokujika kokujika, ngakho-ke ukulawulwa kwe-precisioin kwama-capacitor cores kuba ubuchwepheshe obuyinhloko.I-winding of capacitor core ngokuvamile yenziwa ngesivinini esikhulu.Njengoba inani lokujika elijikajikayo lithinta ngokuqondile inani lomthamo, ukulawulwa kwenani lokujika okujikajika nokubala kudinga ukunemba okuphezulu, okuvame ukufezwa ngokusebenzisa imojula yokubala enesivinini esiphezulu noma inzwa enobuqiniso bokubona okuphezulu.Ukwengeza, ngenxa yemfuneko yokuthi ukungezwani kwezinto ezibonakalayo kushintshe kancane ngangokunokwenzeka phakathi nenqubo yokusonta ( uma kungenjalo okubalulekile kuzonyakaza nakanjani, kuthinte ukunemba komthamo), ukusonga kufanele kusebenzise ubuchwepheshe bokulawula obusebenzayo.

Ukulawulwa kwesivinini okuhlukaniswe izingxenye kanye nokusheshisa/ukunciphisa okunengqondo kanye nokucubungula isivinini esiguquguqukayo kungenye yezindlela eziphumelela kakhulu: isivinini sokuvunguza esihlukile sisetshenziselwa izikhathi zokusonta ezahlukene;phakathi nenkathi yesivinini esiguquguqukayo, ukusheshisa nokunciphisa kusetshenziswa ngamajika ejubane aguquguqukayo ukuze kuqedwe i-jitter, njll.

3. I-Demetallization Technology

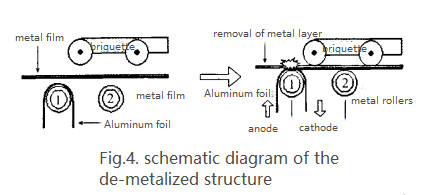

Izendlalelo eziningi zezinto zilinyazwa phezu kwesinye futhi zidinga ukwelashwa kokuvala ukushisa ngaphandle kanye nesixhumi esibonakalayo.Ngaphandle kokwandisa impahla yefilimu yepulasitiki, ifilimu yensimbi ekhona isetshenziswa futhi ifilimu yayo yensimbi isetshenziswa futhi ukucwecwa kwayo kwensimbi kususwa ngenqubo yokukhishwa kwe-metalization ukuze kutholwe ifilimu yepulasitiki ngaphambi kophawu lwangaphandle.

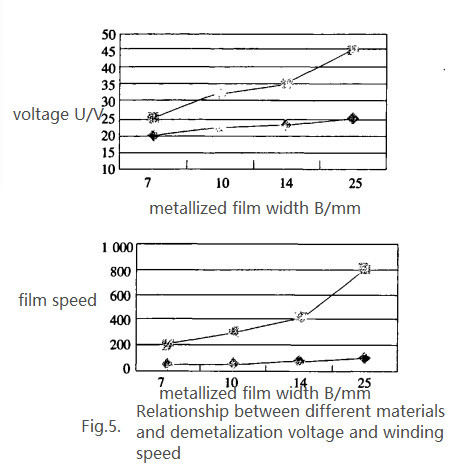

Lobu buchwepheshe bungasindisa izindleko zempahla futhi ngesikhathi esifanayo bunciphise ububanzi bangaphandle be-capacitor core ( uma kwenzeka umthamo olinganayo wengqikithi).Ukwengeza, ngokusebenzisa ubuchwepheshe be-demetalization, ukumbozwa kwensimbi kwesendlalelo esithile (noma izingqimba ezimbili) zefilimu yensimbi kungasuswa kusenesikhathi ku-interface eyinhloko, ngaleyo ndlela kugwenywe ukwenzeka kwesifunda esifushane esiphukile, esingathuthukisa kakhulu isivuno. kwama-coiled cores.Kusukela ku-Figure.5, kungaphetha ngokuthi ukufeza umphumela ofanayo wokususa.I-voltage yokususa yakhelwe ukuthi ikwazi ukushintshwa isuka ku-0V iye ku-35V.Ijubane kumele lehliswe libe phakathi kuka-200r/min kanye no-800 r/min ukuze kuqedwe ukuqina ngemva kokusonteka kwesivinini esikhulu.I-voltage ehlukene nesivinini singasethwa emikhiqizweni ehlukene.

4. Ubuchwepheshe bokuvalwa kokushisa

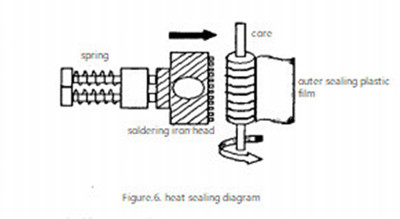

Ukuvalwa kokushisa kungenye yobuchwepheshe obubalulekile obuthinta ukufaneleka kwama-nxeba capacitor cores.Ukuvalwa kokushisa ukusebenzisa insimbi yokushisa esezingeni eliphezulu ukuze kuhlinzeke futhi kuhlanganiswe ifilimu yepulasitiki endaweni ehlanganayo ye-coiled capacitor core njengoba kuboniswe kuMfanekiso.6.Ukuze umgogodla ungagoqeki ngokukhululekile, kuyadingeka ukuthi uboshwe ngokuthembekile futhi ubuso bokuphela buyisicaba futhi bubuhle.Izinto ezimbalwa eziyinhloko ezithinta umphumela wokuvala ukushisa izinga lokushisa, isikhathi sokuvala ukushisa, i-core roll nesivinini, njll.

Ngokuvamile, izinga lokushisa lokuvalwa kokushisa liyashintsha ngokushuba kwefilimu nezinto ezibonakalayo.Uma ubukhulu befilimu bento efanayo bungu-3μm, izinga lokushisa lokuvalwa kokushisa liphakathi kuka-280 ℃ no-350 ℃, kuyilapho ukushuba kwefilimu kungu-5.4μm, izinga lokushisa lokuvalwa kokushisa kufanele lilungiswe ukuze libe nobubanzi befilimu. 300cc kanye 380cc.Ukujula kokuvalwa kokushisa kuhlobene ngokuqondile nesikhathi sokuvalwa kokushisa, i-crimping degree, izinga lokushisa le-soldering iron, njll. Ukuqonda ukujula kokuvalwa kokushisa nakho kubaluleke kakhulu ukuthi ama-capacitor cores afanelekayo angakhiqizwa yini.

5. Isiphetho

Ngokucwaninga nokuthuthukiswa eminyakeni yamuva, abakhiqizi abaningi bemishini yasekhaya baye bahlakulela imishini yokufaka ifilimu ye-capacitor.Eziningi zazo zingcono kunemikhiqizo efanayo yasekhaya nakwamanye amazwe ngokobukhulu bezinto ezibonakalayo, isivinini esimazombezombe, umsebenzi we-demetallization kanye nohlu lomkhiqizo osongwayo, futhi zinezinga lobuchwepheshe elithuthukile lamazwe ngamazwe.Nansi incazelo emfushane kuphela yobuchwepheshe obubalulekile bobuchwepheshe bokuphehla ifilimu, futhi sithemba ukuthi ngokuqhubeka okuqhubekayo kobuchwepheshe obuhlobene nenqubo yokukhiqiza ifilimu yasekhaya, singathuthukisa ukuthuthuka okunamandla kwemboni yemishini yokukhiqiza ifilimu e-China. .

Isikhathi sokuthumela: Mar-15-2022