Kuleli sonto, sizoba nesingeniso kubuchwepheshe bokugoqa i-capacitor yamafilimu ensimbi. Lesi sihloko sethula izinqubo ezifanele ezihilelekile emishinini yokugoqa i-capacitor yamafilimu, futhi sinikeza incazelo eningiliziwe yobuchwepheshe obubalulekile obuhilelekile, njengobuchwepheshe bokulawula ukungezwani, ubuchwepheshe bokulawula ukugoqa, ubuchwepheshe bokususa insimbi, kanye nobuchwepheshe bokuvala ukushisa.

Ama-capacitor efilimu asetshenziswe kabanzi ngenxa yezici zawo ezinhle kakhulu. Ama-capacitor asetshenziswa kabanzi njengezingxenye eziyisisekelo ze-elekthronikhi ezimbonini ze-elekthronikhi njengezinto zasekhaya, ama-monitor, izinto zokukhanyisa, imikhiqizo yokuxhumana, izinsiza zikagesi, izinsimbi, amamitha kanye namanye amadivayisi kagesi. Ama-capacitor asetshenziswa kakhulu ama-capacitor e-dielectric ephepha, ama-capacitor e-ceramic, ama-capacitor e-electrolytic, njll. Ama-capacitor efilimu athatha kancane kancane imakethe enkulu nankulu ngenxa yezici zawo ezinhle kakhulu, njengosayizi omncane, isisindo esincane. Amandla azinzile, ukuvimba okuphezulu kokushisa, impendulo ebanzi yemvamisa kanye nokulahleka okuncane kwe-dielectric.

Ama-capacitor efilimu ahlukaniswe cishe kanje: uhlobo olune-laminated kanye nohlobo lwenxeba ngokwezindlela ezahlukene zokucubungula i-core. Inqubo yokugoqa i-capacitor yefilimu eyethulwe lapha ikakhulukazi imayelana nama-capacitor avamile okugoqa, okungukuthi ama-capacitor cores enziwe nge-foil yensimbi, ifilimu eyenziwe ngensimbi, ifilimu yepulasitiki nezinye izinto (ama-capacitor ajwayelekile, ama-capacitor aphezulu, ama-capacitor okuphepha, njll.), asetshenziswa kabanzi kuma-timing, oscillation kanye nama-filter circuits, i-frequency ephezulu, i-pulse ephezulu kanye ne-high current events, ama-screen monitors kanye ne-color TV line reverse circuit, i-power supply cross-line noise reducing circuit, i-anti-interference events, njll.

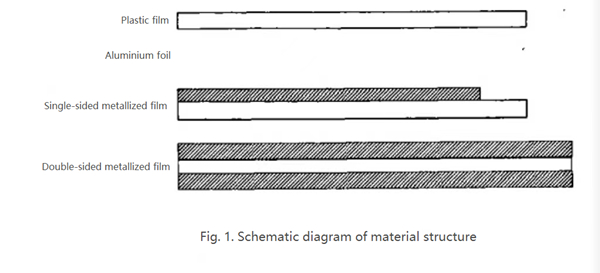

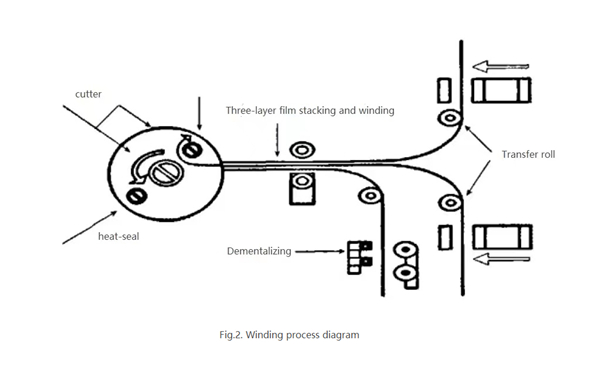

Okulandelayo, sizokwethula inqubo yokugoqa ngokuningiliziwe. Ubuchwepheshe bokugoqa i-capacitor busetshenziswa ifilimu yensimbi egoqayo, i-foil yensimbi kanye nefilimu yepulasitiki enkabeni, bese kubekwa ukujika okuhlukile kokugoqayo ngokuya ngomthamo we-capacitor core. Lapho inani lokujika kokugoqa lifinyelelwa, izinto ziyanqunywa, futhi ekugcineni ukuphuka kuyavalwa ukuze kuqedwe ukugoqa kwe-capacitor core. Umdwebo wesakhiwo sezinto ezibonakalayo uboniswe ku-Fig. 1. Umdwebo wesakhiwo senqubo yokugoqayo uboniswe ku-Fig. 2.

Kunezici eziningi ezithinta ukusebenza kwe-capacitance ngesikhathi senqubo yokugoqa, njengokuthamba kwethreyi yokulenga yezinto, ukushelela kobuso be-transition roller, ukucindezeleka kwezinto ezigoqayo, umphumela we-demetalliazion wezinto zefilimu, umphumela wokuvala lapho kuphuka, indlela yokugoqa izinto ezigoqayo, njll. Konke lokhu kuzoba nomthelela omkhulu ekuhlolweni kokusebenza kwe-capacitor core yokugcina.

Indlela evamile yokuvala ingxenye engaphandle ye-capacitor core iwukuvala ukushisa nge-soldering iron. Ngokufudumeza ingxenye yensimbi (izinga lokushisa lincike enqubweni yemikhiqizo ehlukene). Uma kwenzeka ukujikeleza okuphansi kwe-core egoqiwe, ingxenye yensimbi egoqiwe ixhunyaniswa nefilimu yokuvala yangaphandle ye-capacitor core bese ivalwa nge-hot stamping. Ikhwalithi yesivalo ithinta ngqo ukubukeka kwengxenye.

Ifilimu yepulasitiki ekugcineni kokuvala ivame ukutholakala ngezindlela ezimbili: eyodwa iwukufaka ungqimba lwefilimu yepulasitiki endaweni yokugoqa, okwandisa ukujiya kwengqimba ye-capacitor dielectric futhi kwandisa ububanzi be-capacitor core. Enye indlela iwukususa i-metal film coating ekugcineni kwe-winding ukuze kutholakale ifilimu yepulasitiki ene-metal coating esusiwe, okunganciphisa ububanzi be-core ngomthamo ofanayo we-capacitor core.

Isikhathi sokuthunyelwe: Mashi-01-2022